The History and Evolution of the Wheel: Wheel Definition

The wheel, one of humanity’s most ingenious inventions, has revolutionized transportation, agriculture, and countless other aspects of civilization. Its humble origins can be traced back to ancient times, with the earliest known examples appearing in Mesopotamia around 3500 BCE. This remarkable invention has undergone a fascinating journey of evolution, with its design and functionality adapting to meet the changing needs of societies throughout history.

Early Examples and Uses, Wheel definition

The earliest wheels were likely solid wooden disks, used primarily for moving heavy objects. These early wheels were often attached to sleds or carts, allowing for the transportation of goods and materials over land. The invention of the wheel revolutionized transportation, enabling humans to move heavier loads with less effort, and to travel greater distances in shorter periods of time. The wheel also played a crucial role in the development of agriculture, facilitating the transportation of crops and livestock, and allowing for the cultivation of larger areas of land.

Types of Wheels and Their Applications

Wheels, the seemingly simple invention that revolutionized transportation and industry, come in an astounding variety, each tailored to a specific purpose. These variations are not just aesthetic; they represent a fascinating interplay of materials, design, and function, showcasing the wheel’s remarkable adaptability.

Vehicle Wheels

Vehicle wheels, the ubiquitous components that connect vehicles to the road, are broadly categorized based on their intended use and construction.

- Car Wheels: Car wheels are typically made of lightweight alloys, such as aluminum or magnesium, which enhance fuel efficiency. They are designed to provide a balance of strength, durability, and aesthetic appeal. Modern car wheels often feature intricate designs, contributing to the vehicle’s overall style.

- Truck Wheels: Truck wheels, on the other hand, are built for heavy-duty applications. They are usually made of steel, ensuring robustness and load-bearing capacity. Truck wheels often feature a wider diameter and thicker rims to accommodate the higher weight and torque involved in transporting goods.

- Bicycle Wheels: Bicycle wheels are lightweight and aerodynamic, optimized for speed and maneuverability. They are often made of aluminum or carbon fiber, with intricate spoke designs that contribute to their structural integrity and stiffness.

Industrial Wheels

Industrial wheels are essential components in various industrial settings, facilitating the movement of heavy machinery, equipment, and materials.

- Conveyor Wheels: Conveyor wheels are designed to move materials along a conveyor belt. They are typically made of durable materials such as steel or polyurethane, and their size and design vary depending on the weight and type of material being transported. Conveyor wheels are often equipped with bearings to minimize friction and wear.

- Caster Wheels: Caster wheels are small, swiveling wheels that allow for easy movement and maneuverability of objects. They are commonly found on furniture, carts, and industrial equipment. Caster wheels are available in a wide range of materials, including nylon, rubber, and steel, depending on the load capacity and intended application.

- Machine Wheels: Machine wheels are used in various types of machinery, such as cranes, excavators, and construction equipment. These wheels are designed to withstand high loads and harsh operating conditions. They are often made of steel and feature robust construction to ensure reliability and durability.

Other Specialized Wheels

Wheels are not limited to transportation and industry; they have found unique applications in diverse fields.

- Waterwheels: Waterwheels, powered by the flow of water, were historically used for grinding grain and other tasks. They consist of a large wheel with paddles or blades that rotate when submerged in water. Modern waterwheels are still used in some areas for hydroelectric power generation.

- Windmills: Windmills, driven by wind energy, were traditionally used for pumping water and grinding grain. They consist of a large wheel with blades that rotate when exposed to wind. Modern windmills are used for generating electricity on a large scale.

- Gears: Gears are toothed wheels that mesh together to transmit power and motion. They are found in a wide variety of machines, from clocks and watches to automobiles and industrial machinery. Gears are essential for changing speed, direction, and torque in mechanical systems.

The Science and Mechanics of Wheels

The wheel, a seemingly simple invention, is a marvel of engineering that has revolutionized transportation and shaped human civilization. Understanding the science behind its operation reveals the intricate interplay of physics and mechanics that make it possible.

Rolling Motion and Friction

Rolling motion is a fundamental concept in the study of wheels. When a wheel rolls, it experiences a combination of linear and rotational motion. The linear motion is the movement of the wheel’s center of mass along a path, while the rotational motion is the spinning of the wheel around its axis. The key to efficient rolling is minimizing friction.

Friction is a force that opposes motion between two surfaces in contact. In the case of a wheel, friction occurs between the wheel and the surface it rolls on. There are two types of friction that affect rolling motion:

- Rolling friction: This type of friction occurs when a wheel rolls on a surface. It is generally much lower than sliding friction because the contact area between the wheel and the surface is smaller and the deformation of the materials is less.

- Sliding friction: This type of friction occurs when a wheel slides on a surface. It is much higher than rolling friction because the contact area between the wheel and the surface is larger and the deformation of the materials is greater.

The design of a wheel aims to minimize sliding friction and maximize rolling friction. This is achieved through various design features, such as:

- Smooth surfaces: Wheels with smooth surfaces reduce the contact area and deformation, minimizing sliding friction.

- Rounded shape: The rounded shape of a wheel helps distribute the load over a larger area, reducing the pressure and minimizing deformation.

- Materials with low friction coefficients: Materials like rubber or steel have lower friction coefficients, reducing the force required to overcome friction.

Bearings and Axles

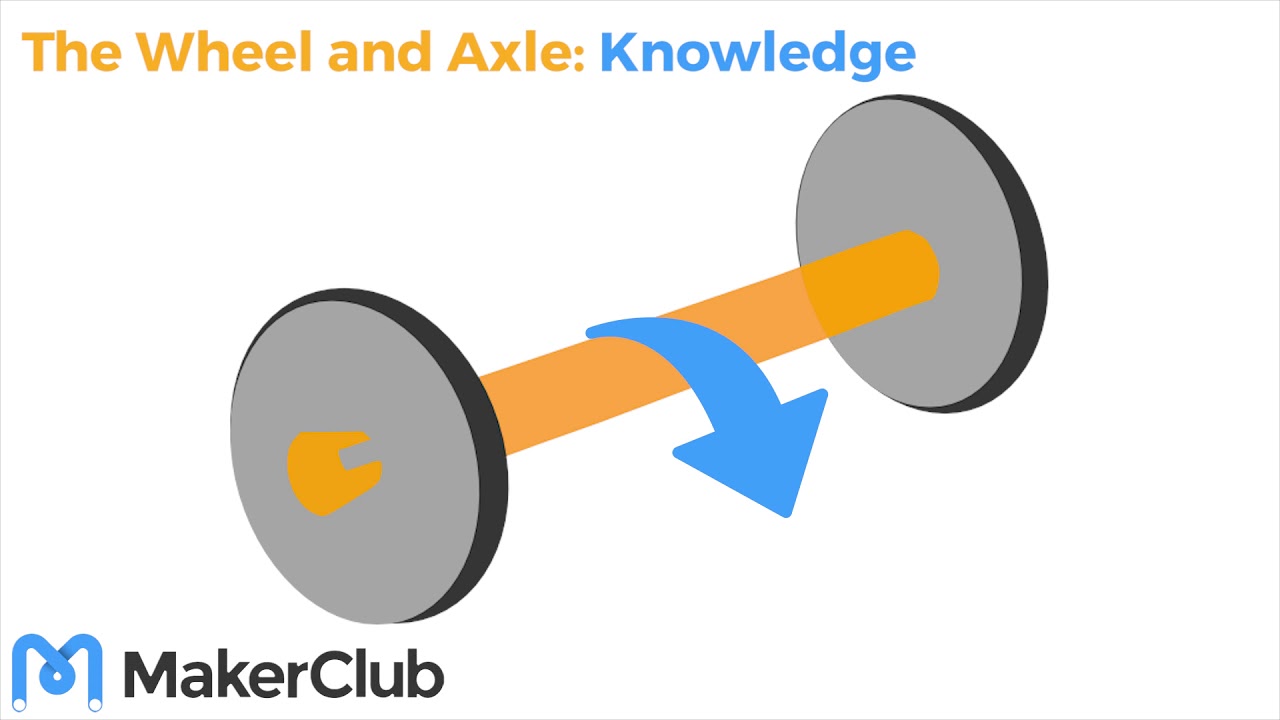

Bearings and axles play a crucial role in reducing friction and enabling smooth rotation of wheels. Bearings are components that support a rotating shaft or axle, allowing it to move with minimal friction. They are typically made of hardened steel or other materials with low friction coefficients.

Axles are shafts that connect the wheels to the vehicle’s frame. They provide the structural support for the wheels and allow them to rotate freely.

The combination of bearings and axles significantly reduces friction, allowing wheels to rotate with minimal resistance. This is crucial for efficient movement and energy conservation.

Factors Influencing Wheel Efficiency

Several factors influence the efficiency and performance of wheels:

- Wheel diameter: Larger wheels have a larger circumference, which means they cover more distance per revolution. This can reduce the number of revolutions required to travel a certain distance, leading to greater efficiency. However, larger wheels also have more inertia, which can make them harder to start and stop.

- Material properties: The material of a wheel affects its weight, strength, and durability. Lighter materials, like aluminum, can reduce the overall weight of the vehicle, improving efficiency. Stronger materials, like steel, can withstand greater loads and provide better durability.

- Load distribution: The way the load is distributed on a wheel affects its performance. Uneven load distribution can cause stress and wear on the wheel and bearings. Proper load distribution ensures that the weight is evenly distributed, minimizing stress and maximizing efficiency.

Experiment: Demonstrating Rolling Motion and Friction

To demonstrate the principles of rolling motion and friction, you can conduct a simple experiment using everyday materials:

- Materials: You will need a smooth, flat surface (like a table), a ball (like a marble or a golf ball), and a piece of cardboard or paper.

- Procedure: Place the ball on the flat surface and gently push it. Observe how the ball rolls smoothly across the surface. Now, place the cardboard or paper on the surface and roll the ball over it. Observe how the ball rolls more slowly and encounters more resistance.

- Explanation: The smooth surface offers less resistance to the rolling ball, resulting in smooth rolling motion. The cardboard or paper, with its rougher surface, creates more friction, slowing down the ball’s movement. This experiment demonstrates the difference between rolling friction on a smooth surface and sliding friction on a rough surface.